Low temperature curable soft conductive resin that maintains conductivity even when stretched

In recent years, electronic devices and sensors have become more flexible, and the use of non-heat resistant materials such as resin is increasing. Therefore, the conductive resin used is also required to have low temperature curability of 100°C or less. In addition, the bonding between the resin material and the metal requires elongation after curing that can follow the difference in linear expansion of the materials, and a flexible conductive resin that does not easily crack when dropped.

Features

- Can be cured at a low temperature of 100°C or less.

- The cured product is soft.

- It does not break and has conductivity even when stretched 100%.

- It can follow the expansion and contraction of the material.

Uses

- Grounding between dissimilar materials with a large difference in coefficient of thermal expansion

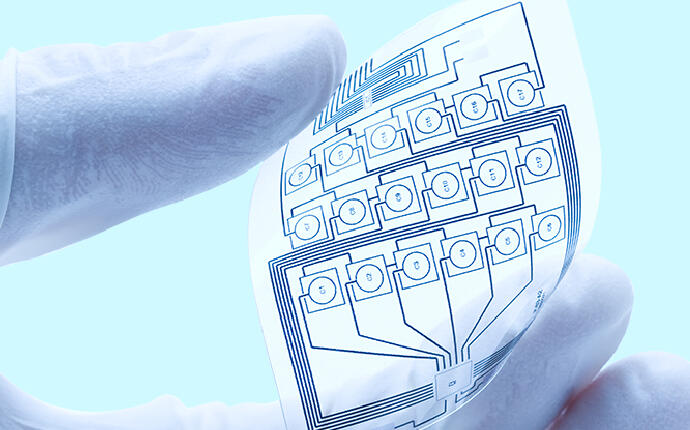

- Grounding of flexible devices and circuit formation

- Mounting electronic components on a flexible board

- Circuit formation of moving parts

Development points

Assuming the response to linear expansion differences between dissimilar materials and application to flexible devices, we have proceeded with the development of a resin that has flexibility not found in conventional products and has conductivity even when deformed. We have succeeded in developing a new product that is softer and more stretchable than before by selecting a silicone resin material that is soft and stretchable as the base polymer and by using a special conductive filler. In addition, by optimizing the curing catalyst, low temperature curing of 100°C or less is achieved.

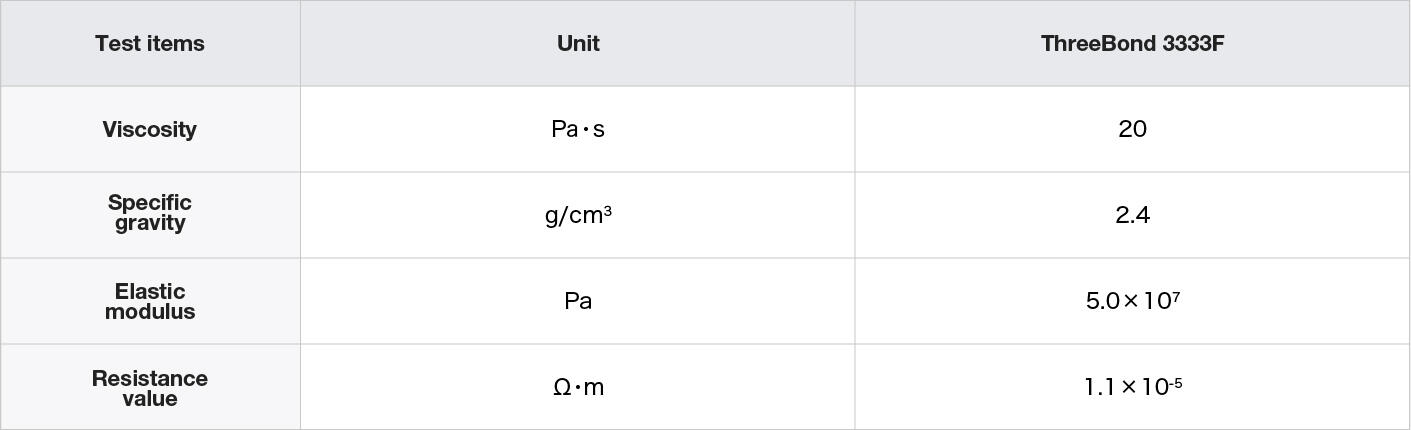

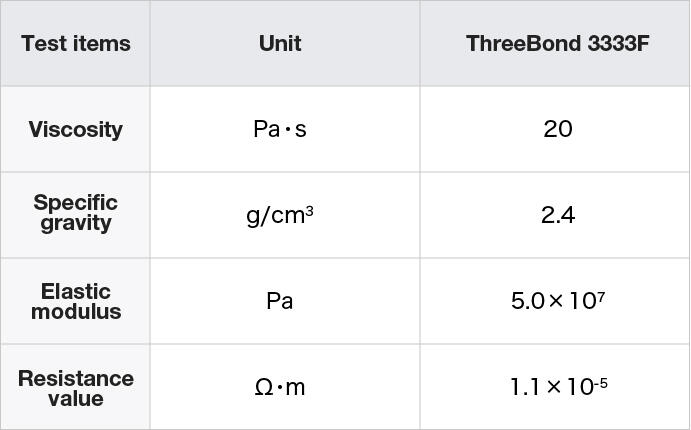

Properties and general characteristics

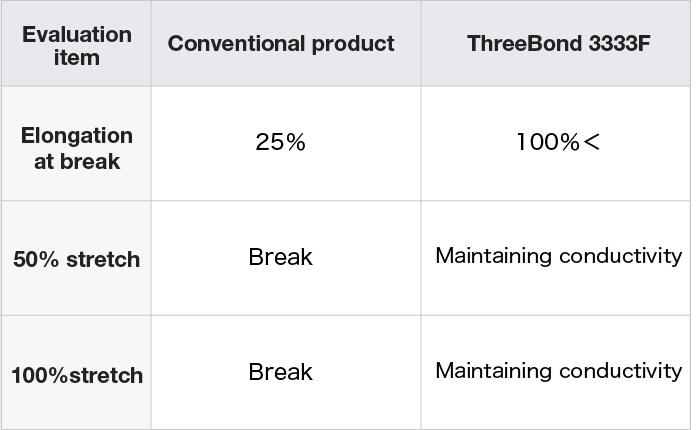

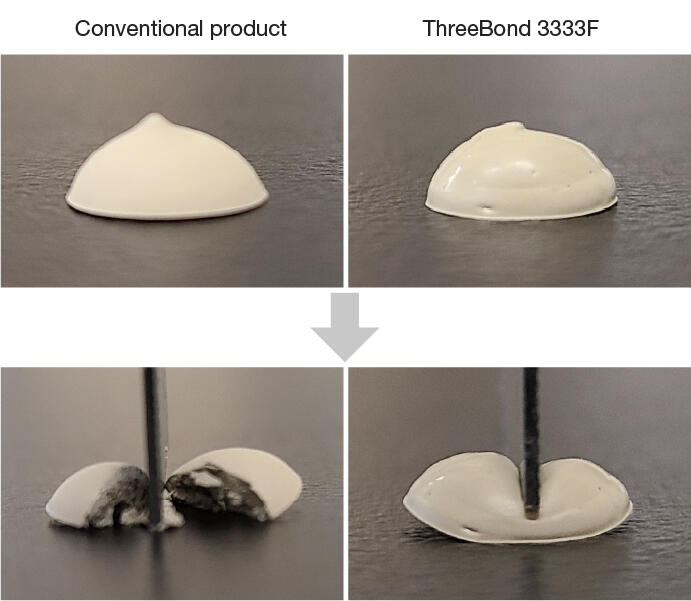

Comparison of hardness with conventional products

When a force is applied to conventional product and the ThreeBond3333F, the conventional product cannot withstand the deformation and breaks, whereas the ThreeBond3333F follows and deforms without breaking due to the force.

Comparison of stretching characteristics with conventional products