UV curing type olefin gasket with long-term water resistance and high gas barrier properties

With the aim of achieving carbon neutrality around the world, the target year for the abolition of automobiles that use internal combustion engines has been set, and the electrification of automobiles will continue to accelerate in the future. Inverters and fuel cells installed in electric vehicles have a water cooling mechanism for cooling the generated heat and a ventilation mechanism for power generation. There is a need for UV-curable gaskets that have high water resistance and high gas barrier properties that make it difficult for gases such as oxygen, hydrogen, and water vapor to permeate, and enable automated processes that shorten production cycle times.

Features

- It has a molecular structure that does not easily deteriorate with water and acid, and has long-term water resistance.

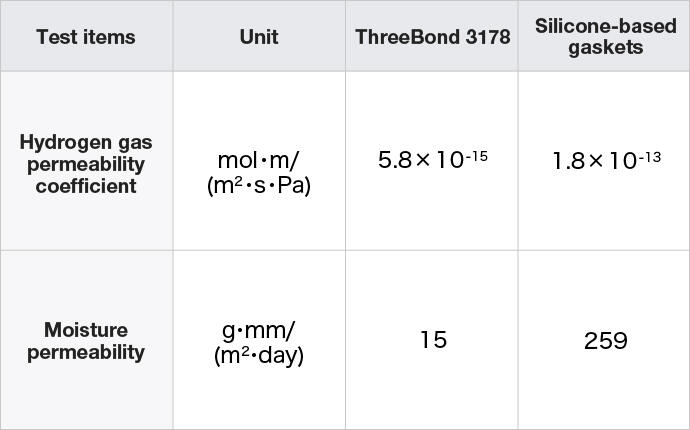

- It has a high gas barrier property against gases such as oxygen and hydrogen.

- The cured product is flexible and elastic, and has restoring force after compression.

- Gaskets can be molded by automatic coating and UV curing.

Uses

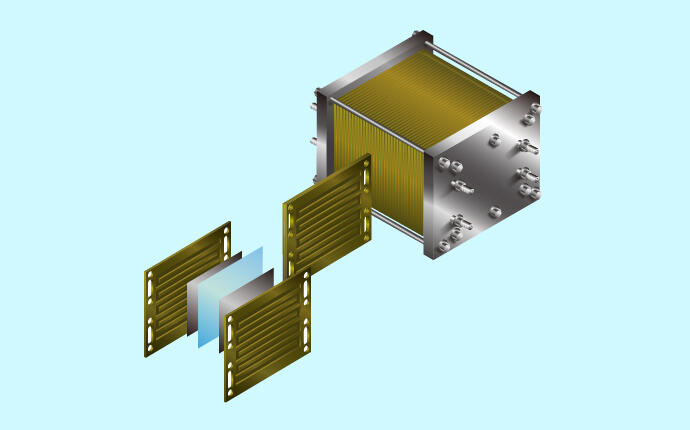

- Seal of gas and liquid flow path of fuel cell

- Seal of the water flow path of the inverter

- Steam seal of electrical parts

Development points

We have been working on the development and commercialization of UV curing type gaskets that have high water resistance and high gas barrier properties for electric vehicles and also have the original characteristics of gaskets. Aiming for long-term high durability and high gas barrier properties against humidity and gas, which could not be achieved with conventional products, we succeeded in commercialization with a special polyolefin-based polymer that has a patented technology. In addition, the product has a liquid property that can be automatically applied to parts with a dispenser and photocuring property that cures in seconds by a light source such as LED, which realizes automation of the gasket assembly process and improvement of productivity.

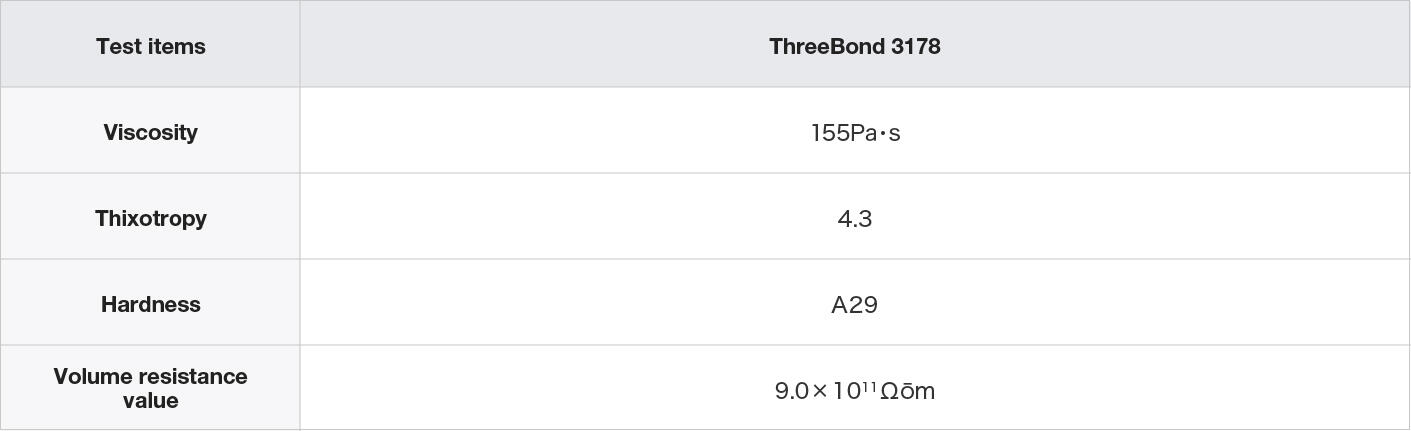

Properties and general characteristics

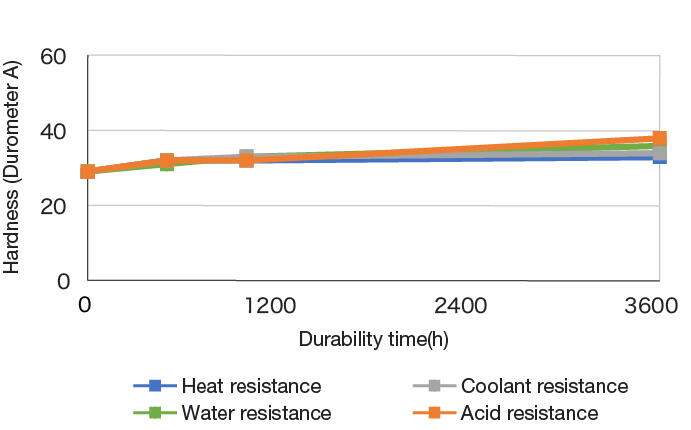

Gasket durability evaluation

(Conditions)

Heat resistance: 120°C

Water resistance: pure water 95°C

Coolant resistance: 50 vol% pure water diluted coolant 95°C

Acid resistance: hydrofluoric acid(100ppm) 95°C

ThreeBond3178 does not change significantly from the initial stages to 3600 hours in terms of heat resistance, water resistance, coolant resistance, and hydrofluoric acid resistance.

Properties and general characteristics