High-strength, impact-resistant structural one-part heat curing type epoxy adhesive

In recent years, automobile manufacturers have been promoting weight reduction of vehicles and bodies for the purpose of reducing greenhouse gas emissions and improving fuel efficiency. Consideration is underway to replace the currently adopted steel sheet with resin members and non-ferrous metals such as aluminum, and as a structural adhesive, it is necessary to have both high shear adhesion strength and peel strength to aluminum and CFRP, in addition to steel sheet. Furthermore, there is a need to develop new structural adhesives that have impact resistance, long-term durability, low-temperature curability, ability to adhere to oily surface, etc., compared to conventional products.

Features

- High adhesive strength and high impact resistance.

- High viscosity with less drippage.

- Excellent durability.

- Can be cured at low temperature and has good storage stability.

- Good ability to adhere to oily surfaces.

Uses

- Adhesion of various structural materials such as steel plates

- Weld bond

- Adhesion of parts that require long-term durability

Development points

Structural adhesives that contribute to reducing the weight of the vehicle body are required to have high shear adhesive strength, peel strength, and longer-term durability than conventional products. In order to meet this demand, we worked on the development of a new product and succeeded in commercializing it by adding a special polymer component to materials based on epoxy resin. The developed product has high adhesive strength and excellent impact resistance and it has properties such as wash-resistant viscosity, thixotropy, low-temperature curability, and ability to adhere to oily surfaces.

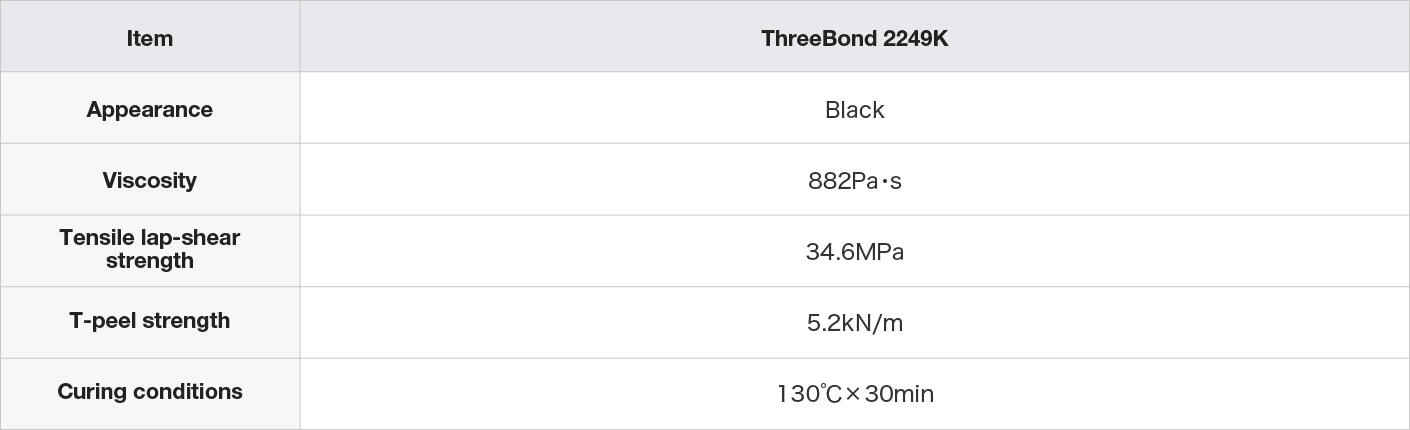

Properties and general characteristics

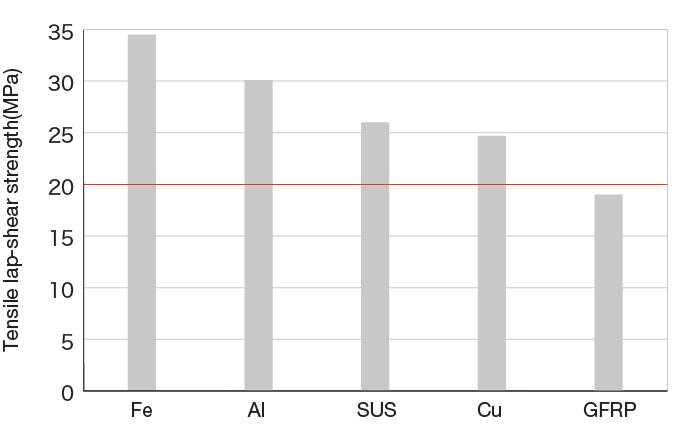

Adhesion to various materials

In addition to impact resistance, it has excellent adhesion to various materials, and can be used for reinforcement of dissimilar material joints where it is difficult to secure strength by welding iron and aluminum.

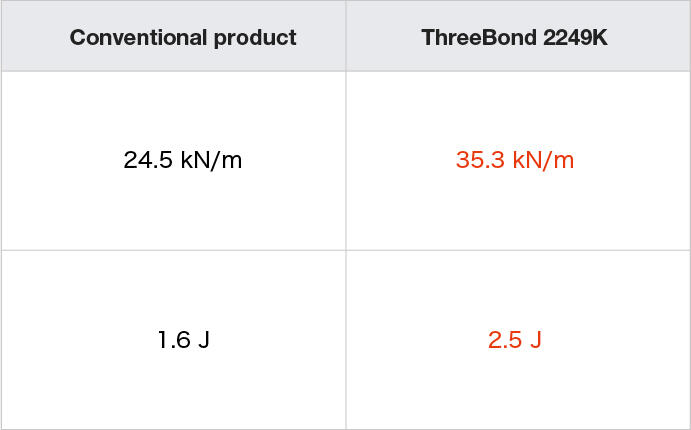

Comparison of impact resistance